Commercial Truck Alignment with ACME Tires!

If your vehicle is driving a little off or your tires are wearing unevenly, it might be out of alignment. Alignment is one of the key parts of your vehicle performance and tire life. As we continue to look for ways to better serve our customers, the addition of alignment services helps them protect their tire investment. Our alignment service offering fits into our preventative maintenance solutions portfolio however most complaints from customers are usually the result of worn out suspension parts and cannot be solved by an alignment alone. It is always best to have a truck inspected before performing an alignment or buying new tires.

When should a truck be aligned?

It is recommended subsequent alignments be done every 80,000 to 100,000 miles. Get your alignments done at about the same intervals as replacing steer tires.

Where do alignment problems originate?

Commercial tire wear problems may show up on steers, but may be coming from the drive or the trailer axles, which can have a huge effect on overall vehicle alignment.

However, even if your commercial vehicle going straight without any pulling or your tires wear evenly that does not mean you have a perfect alignment as your drive tires thrust and scrub angle may absorb each other and have a vehicle going straight but at the same time causing much faster tire wear.

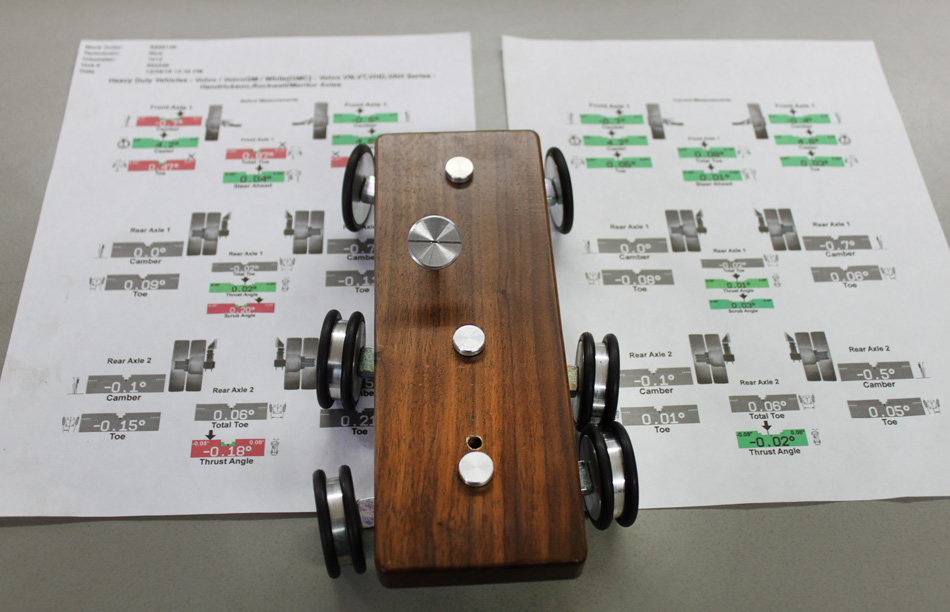

Toe, thrust and scrub angle are the three most critical alignment settings for tire wear.

Excess or too little toe will make the front wheels fight each other, thus increasing wear. An out-of-toe condition leads to rapid inside or outside wear of steer tires.

Should good alignment eliminate irregular wear?

Once irregular wear starts on a steer or trailer tire, there is no way to counteract it. Unfortunately, it’s just going to continue to get worse. If you put new tires on after you align, they should wear evenly, but your old tires are going to continue to show irregular wear. Also, bear in mind that there’s a difference between a vehicle that’s aligned to “spec” and one that’s aligned to “tire wear.”

Understanding alignment specs

The manufacturers establish alignment specs because that’s the result of their experience of what works best, based on average conditions of use. Factory specifications are too broad and can still have problems. The reason for that is the manufacturers want to crank out truck quickly and spend less time at the end of the assembly line. Understanding your truck alignment is your sole obligation, that is why professionals in Acme Truck Tires team will help you get the knowledge you need and the ability to diagnose commercial tire wear and also prevent future unnecessary expenses caused by alignment.

But your conditions may not be “average.” You may haul much heavier or much lighter loads. You may have greater or less road crown along your routes. There are so many operational variables. If you think about road crown, for example, it’s trying to push the vehicle off the road onto the shoulder. If the vehicle were aligned for a perfectly flat road, the driver would have to be constantly applying force to the steering wheel to keep the vehicle on a crowned road. So, alignment specs try to take things like that into account.

How to determine if the truck is truly properly aligned?

Tire wear is the best indicator. Your tires will tell you whether your axles are properly aligned by how long they last. Correct inflation pressure and correct alignment are the two biggest factors in long tire life.